Based on the Environment & Safety Policy, to prevent occupational accidents in the workplace, and promote employee health and develop a comfortable work environment, the Group operates management systems in accordance with Guidelines on Occupational Safety and Health Management Systems (OSHMS) presented by the Ministry of Health, Labour and Welfare.

In addition, the Group conducts regular internal safety audits to verify that safety management, legal compliance, and activities to ensure safety are being conducted in an appropriate manner, working to make improvements to workplace environments while striving to foster employee awareness of safety through education and training.

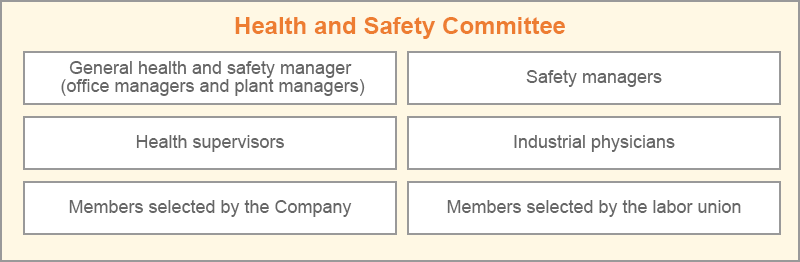

At Group offices, we have established the Health and Safety Committee, which meets once a month, as a structure for ensuring employee safety and health and creating a comfortable work environment. The committee consists of general health and safety managers (office managers and plant managers), safety managers, health supervisors, occupational physicians, and members selected by the Company and labor union.

The committee reports on health and safety activities and discusses important policies for preventing occupational accidents and health disorders of employees, as well as for promoting employee health. The matters reported and discussed by the committee are communicated to all employees through measures such as the health and safety meetings held by each division.

At the Group, each office formulates health and safety objectives and implementation plans, and proactively institutes health and safety activities such as hazard recognition training, near-miss prevention activities, and workplace inspections, etc. They also engage in periodic risk assessment to identify potential workplace risks and implement measures to alleviate them. Additionally, to prevent occupational accidents, it is important to maintain and strengthen environmental and safety management capabilities, and to enhance the awareness of each employee regarding risk, and we are endeavoring to enhance proactive, self-directed problem-solving abilities (on-site capabilities) through safety education and training.

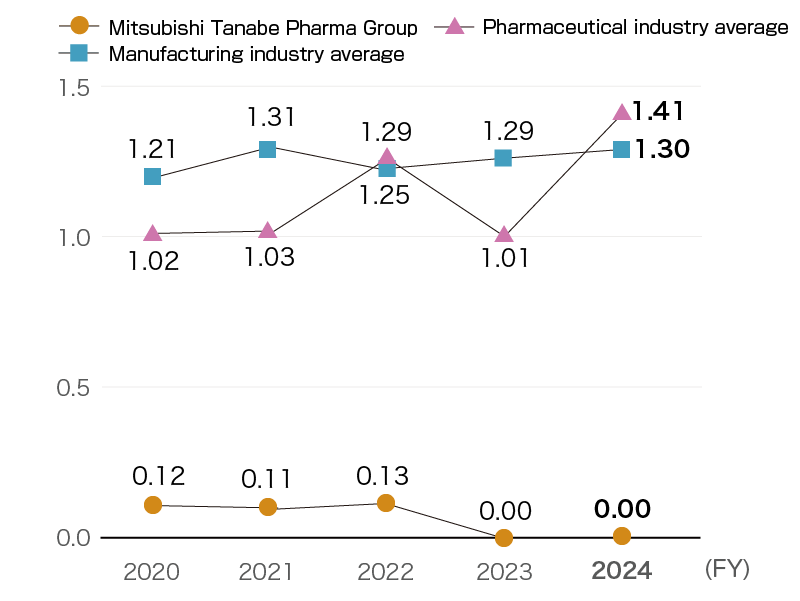

In fiscal 2024, as a result of a range of safety measures, there were no lost time injuries in our operations in Japan, where we thus achieved our goal of a frequency rate of less than 0.20 lost time injuries. (There were also no incidences of lost time injury overseas.)

Lost time injury frequency rate

-

Lost time injury frequency rate:

Number of casualties due to accidents that require time off from work up to one million actual working hours (excluding commuting injuries).

-

Calculation period:

For the Group, April to March the next year; for pharmaceutical industry averages and manufacturing industry averages, January to December.

-

Scope:

All Group offices in Japan

-

Total working hours:

Scope has included permanent employees, contract employees (including some part-time employees), and temporary employees. For permanent employees and contract employees, the indicator is calculated as actual work hours; for temporary employees, it is calculated as work hours per day x number of business days x number of employees.

- Legal compliance and worker obligations training

- Legal compliance and safety and health duty of care training

- Hazard recognition training

- Human error prevention training

- Risk assessment training (including chemical substances)

- Static electricity training workshop

- Experiential training (fires and explosions, burns/chemical injuries, getting caught in or between equipment, handling of electricity)

- Traffic safety training

- 拡大

- Experiential training (caught-in or -between hazards)

As a company that handles many substances, including pharmaceuticals, the Group has established internal regulations related to chemical substances including its Detailed Regulations on Chemical Substance Control, which sets forth the proper handling of those substances.

Accordingly, potential risks are now evaluated in advance (risk evaluation of chemical substances) from the perspectives of both dangerous and hazardous and exposure of people and the environment. We are taking steps to prevent accidents and disasters related to chemical substances by systematically implementing risk management and mitigation measures from obtaining chemical substances to their storage, transport, use and disposal.

The Detailed Regulations on Chemical Substance Control also specify measures to prevent or mitigate environmental pollution, damage to health, and fires or explosions caused by hazardous materials, and all employees at each office are continuously engaged in these measures.

Regarding these activities related to chemical substances, we conduct regular safety audits to comply with laws and regulations.

In accordance with new chemical substance regulations in the Industrial Safety and Health Law that came into effect in 2023, the Group is appropriately managing and controlling additional regulated substances each year in accordance with laws and regulations.

To prevent safety-related accidents, the Group identifies risks at each office, prioritizing them and examining measures for their removal or reduction. These measures are incorporated into the next fiscal year’s equipment investment plan, steadily advancing our improvement of unsafe facilities and equipment.

Additionally, we use safety assessments and horizontal application of near-miss reviews to implement appropriate safety measures in dangerous locations as needed and to prevent accidents and disasters before they occur.

Since fiscal 2011, the Group has implemented employee surveys at Group companies in Japan to gain a comprehensive understanding of employee attitudes toward their jobs and of the Company’s workplace health and safety environments in order to improve management initiatives. From fiscal 2019 we expanded the scope of these initiatives to include overseas Group companies.

As a result of the activities in fiscal 2024, we have on the whole maintained a good work environment and employee vitality. Based on some of the issues that have been found to increase engagement, we are promoting dialogue between management and employees, as well as initiatives at each division.

Note: Information on this page pertains to activities and results for fiscal 2024.